Automation and control for technological process lines

- font size decrease font size increase font size

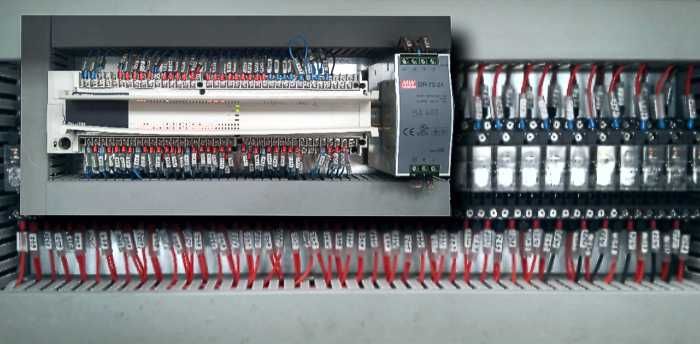

Under the generic title "Automation and control production lines", the company ORIGINAL conducted a series of projects that have involved automation, command and control of a large number of lines and technological processes of the beneficiary.

In these projects, after gathering all necessary information and all beneficiary specifications, were carried out the following activities:

- designing

- manufacturing of electrical distribution, command and control, consoles, etc in our own workshop

- transport and installation to final location

- punere în funcțiune

- commissioning and testing of equipment and technological lines.

The variety of topics covered led to accumulation of valuable experience and allowed us to subsequently provide beneficiary under its systems maintenance, a constant of our work, the professionalism and total commitment in all our actions.

Were made the entire electrical distribution and automation for:

- chrome plating lines

- high-frequency hardening lines

- grinding lines

- neutralization processes

- leveling machine line

- peeling lines

- the power distribution from the output of the medium voltage transformers to the field equipment

- the command and control for the field elements of each technological line, like: sensors, limiters, motors, valves, etc.

Monitoring and process control was achieved with SCADA systems, which allow both supervision and control processes and obtaining statistics on production systems and alarms generated.

Additional Info

- Customer: NIMET - NIMET Romania is a major European producer of hard chrome plated steel bars and tubes, nickel and chrome plated bars and tubes, linear shafts and customized precision shafts on the market of hydraulic lifting, loading and handling systems.